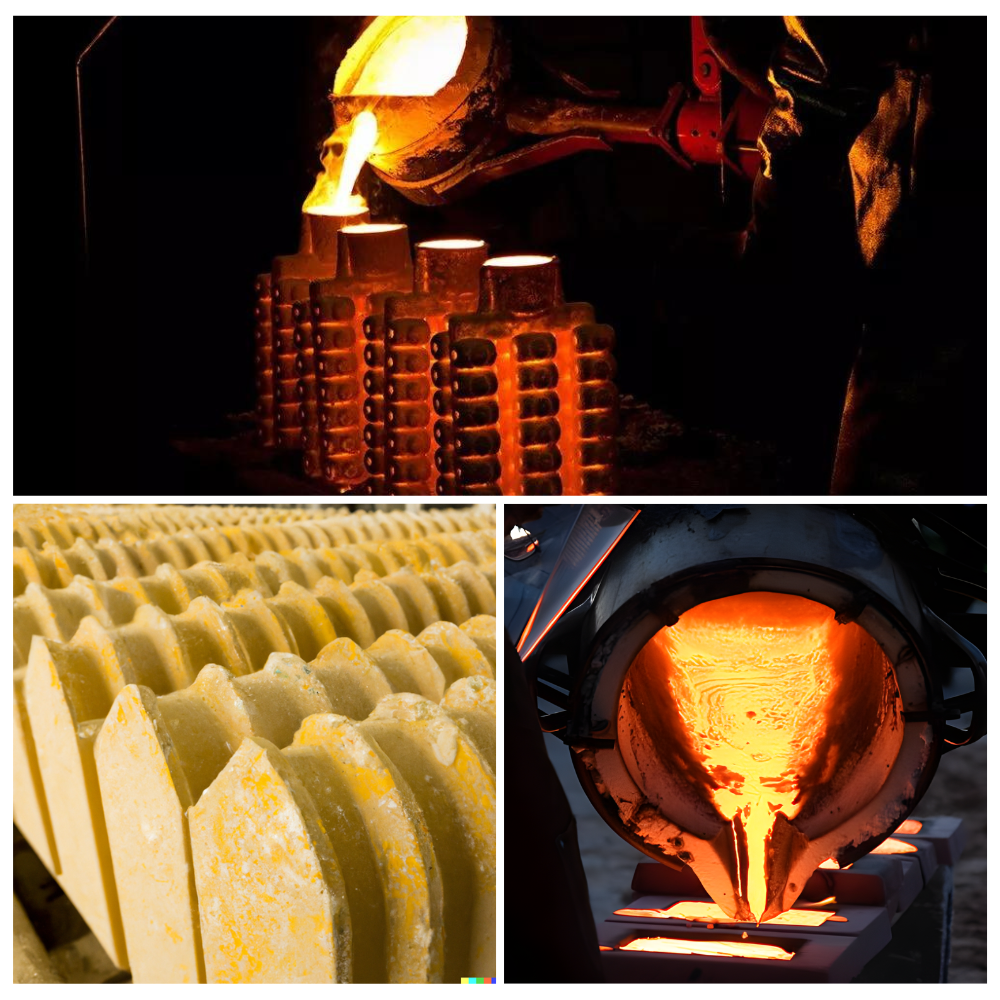

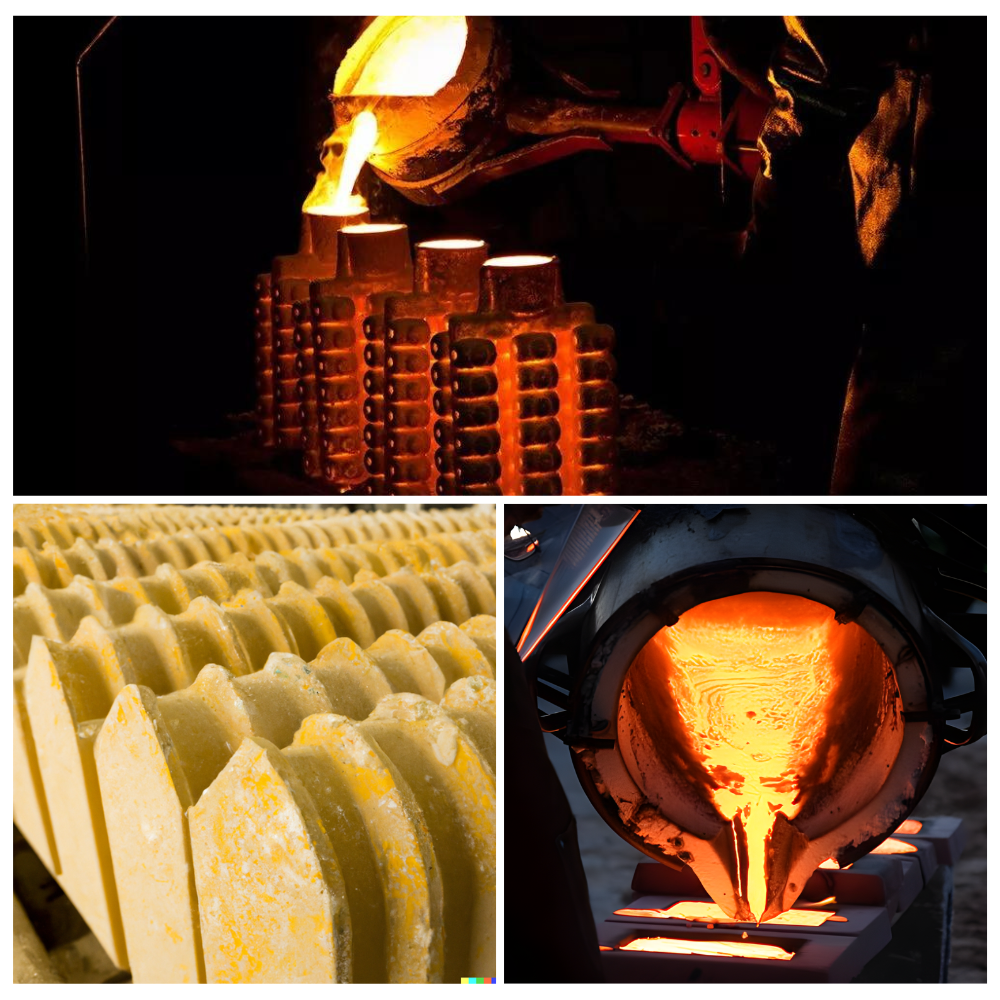

The Foundry Division of SPAC holds certifications in ISO 9001:2015, attesting to its commitment to quality. Specializing in the production of medium to high volume, small to medium-sized castings in Gray Iron and SG Iron, our team, infrastructure, and processes excel in creating intricate Grey Iron and Ductile Iron Castings with utmost precision. To address challenges, the SPAC Team leverages its rapid development capabilities, flexible manufacturing approach, and supporting infrastructure. Additionally, SPAC features an in-house machining facility designed to accommodate various weight, size, and volume requirements.

Our employment of the Shell Moulding Process ensures superior dimensional accuracy, excellent surface finish, and clean internal passages in all our products. Modern facilities, including core shooters, Induction Melting, Spectrometer, Internal shot blasting, and Mechanical testing equipment, contribute to our high-quality standards. We conduct thorough casting inspections with tools such as Endoscopy, Microstructure testing, and hardness testing. Moreover, we have established reliable local partnerships for services like Honing, Casting coating, Heat treatment, etc.

SHELL MOULDING FOUNDRY

SHELL MOULDING FOUNDRY

CASTING RANGE

- Inductotherm Make Induction Furnace 150KG/125KW

- SUSHA Make Shell Molding Machine (Diff. Sizes)

- SPAN Make Shell Core Shooter TSS 300

- SUSHA Make Shell Mold Fusers

- Indabrator Make Tumblasts - WTB 3-6 (100kg)

- Material Handling Crane (2 Ton )

- Inductotherm Induction Furnace - 150KG/125KW

- SUSHA Make Shell Molding Machine (Diff. Sizes)

- SPAN Make Shell Core Shooter TSS 300

- SUSHA Make Shell Mold Fusers

- Indabrator Make Tumblasts - WTB 3-6 (100kg)

- Material Handling Crane (2 Ton)

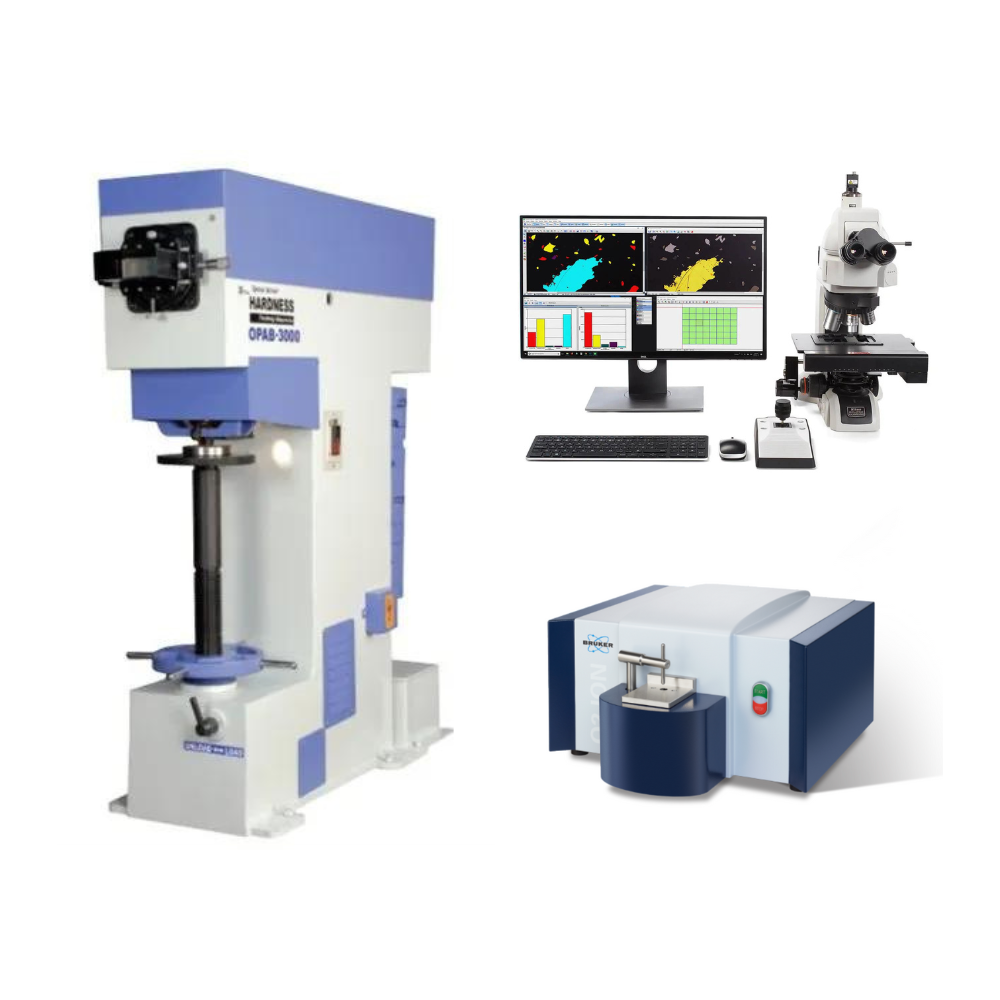

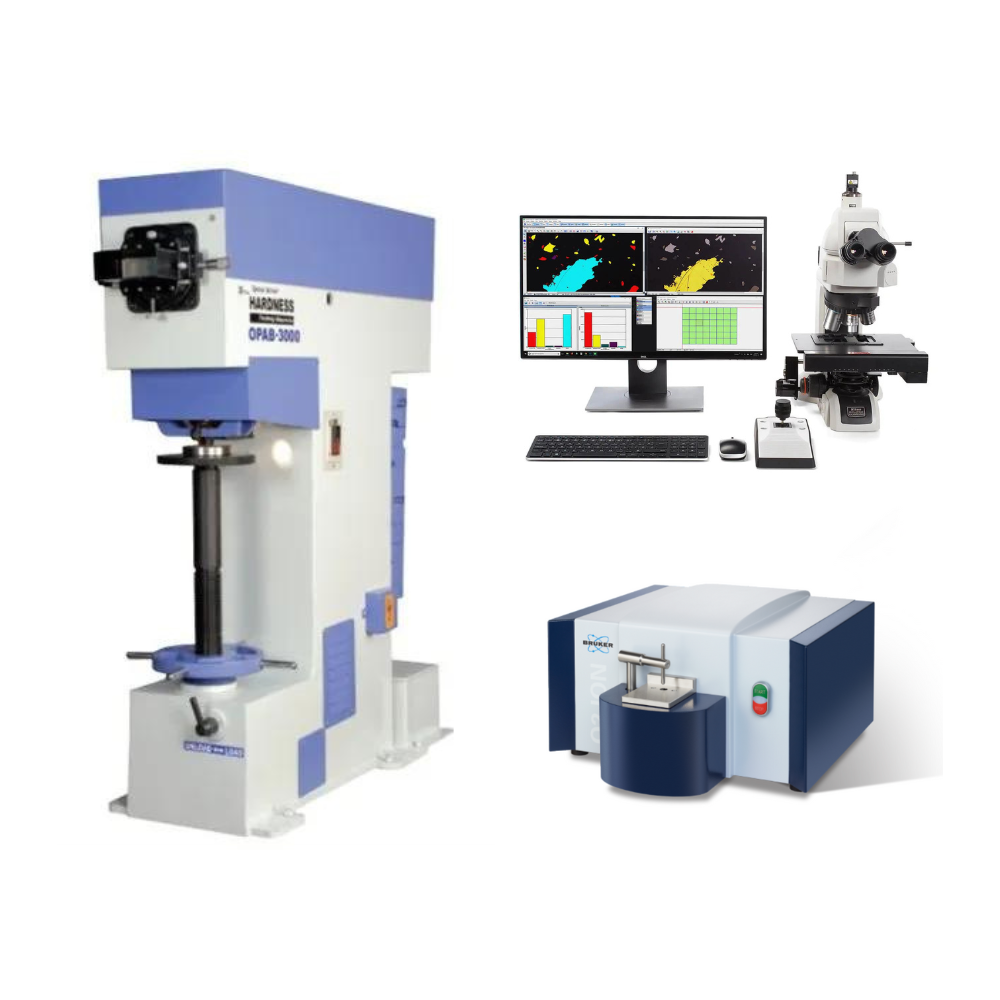

- Brucker (Q2 ION) Make Spectrometer

- Metal Soft Make Microscope & Image Analyzer

- FINE Make Optical Brinell Hardness Tester

- Suyash Solution Make Carbon-Silicon Analyzer

- Versatile Make Shell Sand Testing Equipment

- Metco Make Sample Cutting & Polishing

- Brucker (Q2 ION) Make Spectrometer

- Metal Soft Make Microscope & Image Analyzer

- FINE Make Optical Brinell Hardness Tester

- Suyash Solution Make Carbon-Silicon Analyser

- Versatile Make Shell Sand Testing Equipment

- Metco Make Sample Cutting & Polishing